Solving Tomorrow's Complex Problems today!

410-857-0770

Email: [email protected]

LAI International

1110 Business Pkwy S.

Westminster, MD 21157

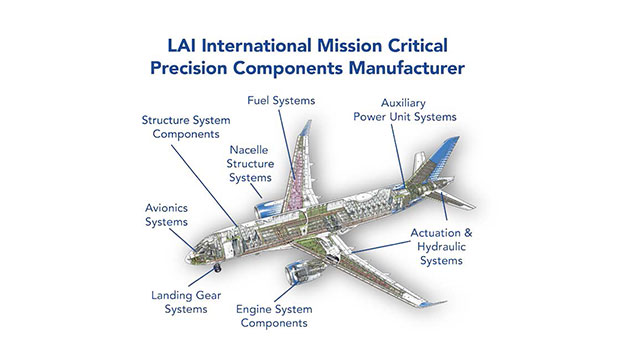

At LAI International, we bring Additive Manufacturing from a prototyping, development technology to a robust production process with our team of experts, and our LAI Business System. As the first Supplier in the world to receive the Additive Manufacturing NADCAP Accreditation, we have all of our quality systems in place to produce conforming parts which meet both your material performance and dimensional expectations.

Our material and technology agnostic strategy allows for LAI's AM growth in capacity and capability to meet your application's specific needs. We work hand in hand with your engineers, procurement teams, and quality representatives to simplify and accelerate the adoption of additive manufactured parts. From development hardware, through full rate production, LAI International partners with our Customers to empower and support them to realize the true benefits of additive manufacturing.

At LAI International, process and quality control of our raw material and machine are paramount to our success as an Aerospace and Defense Supplier of additively manufactured parts. We believe the freedom of design flexibility and optimization opportunities afforded by additive manufacturing are only achievable when paired with a robust development process, which is why our Advanced Product Development (APD) is used by our engineers to bring our Customer's AM parts from concept to reality.

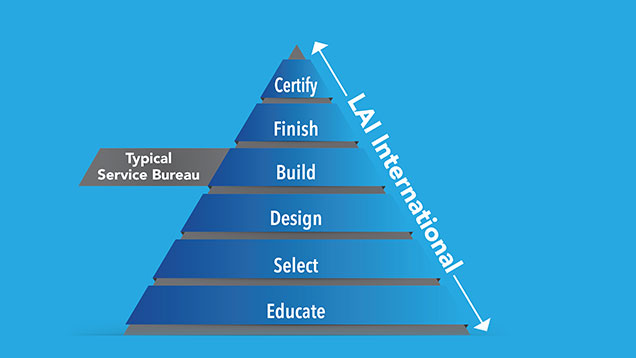

From Introduction to Additive Manufacturing, through Design Principles, Process Selection, Business Case Development, and Validation and Qualification, the LAI Team has an education package to enhance our Customer’s skillsets. We will provide the courses face to face or online, and create customized packages to meet your current AM needs.

Select

Using both quantitative and qualitative assessment tools, the LAI team helps our Customers sort through large quantities of parts to find optimal parts for Additive Manufacturing. The goal of the selection study is driven by our Customers own weighted criteria, from cost & leadtime reduction, weight reduction, performance increase, or more.

The LAI team is enabled with FEA and geometric optimization software, and has the unique capability to take our Customer’s designs meant for conventional manufacturing processes and transforming them into additive parts. These optimizations not only follow the AM design rules, but also increase functionality and properties for mechanics, weight, thermals and more.

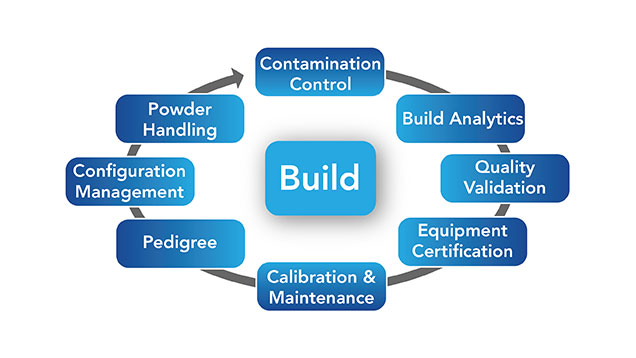

LAI has employed strict standard work along with secure configuration management, best-in-class quality and validation procedures, and unique build analytic tools to ensure our process maintains certification under all AS9100:2008 standards.

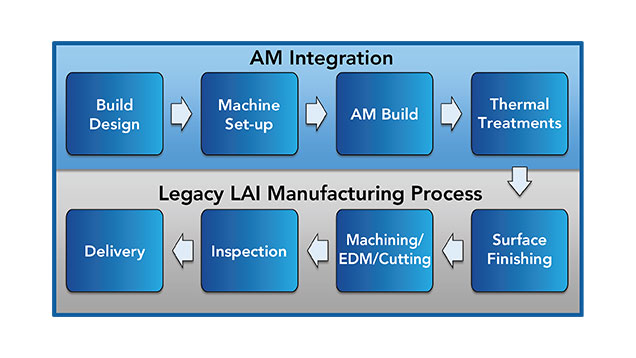

LAI approaches Additive Manufacturing as simply another tool in the manufacturing solution toolbox. The AM Process is fully integrated into the rest of the legacy technologies such as machining, EDM, water jet, laser cutting, etc. LAI provides a full value stream solution to our Customers, delivering final conforming to-print hardware

The LAI Team maintains up to date industry information from our relationships with consortiums, groups and machine OEM’s, contributions to industry specification committees, and discussions with regulatory bodies such as the FAA and DoD. Connecting with AM experts world-wide ensures our in-house practices maintain the expectations of our Customers, enabling us to stay a step ahead of the rest.